An online gas chromatography analysis instrument, also known as an online gas chromatograph (or remote gas chromatograph), is widely used for process monitoring. It automatically and continuously analyzes process data, providing functions like automatic sampling, adjustment, fast data processing, and continuous output of detection quantities.

Definition of Online Gas Chromatography Instrument

The online gas chromatograph is an online analytical instrument that uses separation and selective detection. It has excellent selectivity, high measurement accuracy and analysis accuracy, and a wide range of applications. The analytical instrument of the online gas chromatograph adopts the application requirement definition formula, the maximum length in the system conditions, sensitivity and other measurement parameters. The online gas chromatograph provides a fixed detection process and system configuration function module based on the process site scene requirements and system actual conditions, etc., and has specific properties and stability.

Online gas chromatographs have been widely used in various point sampling controls of industrial processes. They are process controls completed through analytical instruments relative to the available data analysis and control of gas chromatography processes. The analysis procedures of online gas chromatographs include sampling and analysis systems, mass spectrometer test calculations, and more. These instruments are widely used for gas environment analysis, monitoring, and early warning. In recent years, driven by market demand for environmental testing, many domestic companies have developed online gas chromatographs using automatic control technology and specialized processing algorithms. These chromatographs are designed for environmental monitoring and are used for the online analysis of waste gas from fixed pollution sources.

Measuring Principle of Online Gas Chromatography

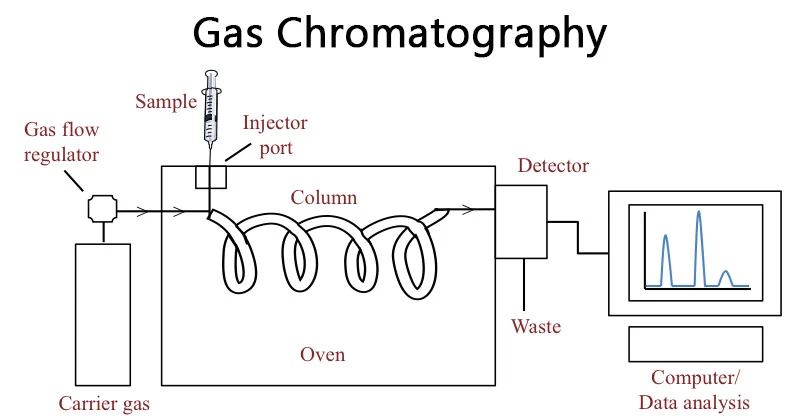

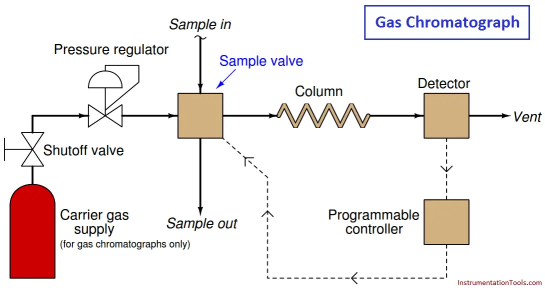

(1) Measurement principle: Gas chromatography (GC) is currently the most widely used chromatographic analysis method. It is an analysis method that uses high-purity gas as the mobile phase (also called carrier gas) to carry the sample into a gas chromatography column coated or filled with a stationary phase for separation.The separation process of gas chromatography is shown in the picture below.

Gas chromatography is suitable for samples that are volatile and thermally stable, and whose boiling point generally does not exceed 500°C. The sample forms include gas and liquid. You can directly introduce the gas sample with a gas quantitative tube. First, inject the liquid sample into the vaporization chamber using a syringe, and then introduce it after vaporization. You generally use 0.55.5 mL of gas sample and 220 µL of liquid sample. A carrier gas with a certain flow rate carries the introduced gas sample into the chromatographic column. The basic requirement for the carrier gas is that it does not react chemically with the sample or the stationary phase, and it is not adsorbed or dissolved by the stationary phase.

Gas chromatography separation technology achieves separation by utilizing the differences in the distribution coefficients of the components in the mixture between the mobile phase and the stationary phase.

Composition of Online Gas Chromatography Analysis Instrument

Carrier gas carries the sample from the injection valve through the chromatographic column to the detector;

the sampling system is used for sample pretreatment of the analyzer;

the sample valve takes a certain volume of gas or liquid sample and allows it to enter the chromatographic column;

the chromatographic column separates the sample mixture into individual components;

the detector detects the separated components separately;

the chromatogram is a spectrum diagram that records the detector’s electrical signal.

System Integration of Online Gas Chromatograph

System Integration The system integration of online gas chromatograph mainly includes: sampling and processing unit, online chromatograph unit, controller unit, auxiliary unit, as well a protective cabinet, analysis room, etc., to meet the requirements of on-site working conditions. For multi-point sampling and analysis of industrial process chromatography, you can use one online chromatograph host with multiple sampling and processing units configured. You can achieve multi-point analysis through multi-valve switching, or you can install multiple online gas chromatographs and multi-point sampling and processing units in the analysis room to complete real-time analysis of each point.

The entire process of online gas chromatography analysis is that the controller automatically samples, processes, analyzes and collects analysis data according to the set program and sends the component analysis information of the online gas chromatograph to the distributed control system (DCS). The information output of the online chromatograph used for environmental monitoring also includes sending the data to the environmental protection department.

(1) Sampling and processing unit

The sampling and processing unit refers to the sampling probe device, sample pretreatment system, and flow path processing and switching unit of the online gas chromatograph. The process gas containing dust, water and interfering components is first sampled by the sampling probe device and processed by the sample pretreatment system to become a clean and dry sample, and then enters the flow path processing and switching unit of the online gas chromatograph. The flow path processing and switching unit of the online gas chromatograph mainly has the functions of sample fine filtration, flow pressure regulation, multi-flow path switching and atmospheric balance components. The online gas chromatograph can perform multi-flow and multi-component analysis, and the number of analytical flow paths can reach up to 31 (including calibration flow paths).

(2) Online Chromatographic Analyzer

The analyzer unit mainly consists of an automatic injection valve, chromatographic column system, detector, and constant temperature furnace. The automatic injection valve periodically sends quantitative samples to the chromatographic column. The chromatographic column system separates the mixed components. The detector detects the separated components and generates the corresponding signal. The constant temperature furnace provides a constant temperature for the detector.

The main detectors are: thermal conductivity detector (TCD), hydrogen flame ionization detector (FID), electron capture detector (ECD)

Flame photometric detector (FPD), photoionization detector (PID) and nitrogen phosphorus detector (NPD), etc. The constant temperature furnaces of online gas chromatographs mainly include the following:

the hot wire heated cast aluminum furnace. which has a highest furnace temperature of 130°C and can measure substances with a highest boiling point of 150°C;

the air bath heating furnace, with a highest furnace temperature of 225°C and capable of measuring substances with a highest boiling point of 270°C;

the programmed temperature furnace, which has a highest furnace temperature of 320°C and can measure substances with a highest boiling point of 450°C.

(3) Controller unit

The controller unit includes: furnace temperature control, program control of injection, column switching and flow path switching, detector signal amplification processing and numerical calculation, microcomputer data processing, program control and local display and output, etc.

The microprocessor controller controls the various components in the system to work automatically, coordinately and periodically according to the pre-arranged program. The temperature controller automatically controls the temperature of the chromatographic column thermostat. The weak electrical signal from the detector passes through the amplification circuit and enters the data processing component. In addition to the main components mentioned above, the system also includes gas path control display components, such as those that display the voltage and flow control status of the carrier gas, auxiliary gas, and standard gas entering the instrument, as well as the pressure and flow display. It also includes various voltage-stabilized power supplies, alarm detection sensors, and other components, along with explosion-proof components like various isolation, positive pressure explosion-proof, and intrinsic safety explosion-proof components and their alarm interlocking systems.

System Integration and Technical Application of Online Gas Chromatograph

The technical applications of online gas chromatography mainly include process analysis and control in process industry production, online analysis and monitoring in the field of environmental monitoring, and quality monitoring of other processes.

(1) Application in petrochemical and other process industries

In the production process analysis of process industry, online gas chromatographs are widely used. Take the petrochemical industry as an example. From oil field exploration and development to oil refining, petrochemical product production process analysis and control, and oil quality control, online gas chromatography analysis technology is indispensable. Online chromatography analysis has been involved in the process control of petrochemical enterprises, such as advanced process control (APC), real-time optimization (RTO), etc. Most petrochemical enterprises have achieved online control of online chromatography analysis. The application of online gas chromatography in petrochemical analysis mainly involves chemical composition analysis in oil and gas field exploration, crude oil analysis, refinery gas analysis, simulated distillation, oil product analysis, elemental hydrocarbon analysis, sulfur and nitrogen compound analysis, gasoline additive analysis, aliphatic hydrocarbon analysis, aromatic hydrocarbon analysis, and chromatographic analysis of process.

(2) Application in environmental monitoring

The online analysis application of online gas chromatograph in the field of environmental monitoring mainly includes the analysis and monitoring of ambient air quality, the monitoring of waste gas emissions from fixed pollution sources, and the analysis and monitoring of gases such as water environment and soil environmental pollution. In the analysis of harmful substances in atmospheric environmental pollution and the monitoring of atmospheric environmental quality, online gas chromatography technology is suitable for the continuous monitoring and analysis of trace gas components in the atmosphere of environmental monitoring workstations, as well as toxic and harmful gases such as VOCs and odors from pollution source waste gas, including the continuous monitoring and analysis of gaseous pollutants contained in atmospheric dust and aerosols. In the process of water environment and water quality monitoring, the application of online gas chromatography technology can continuously and accurately analyze the water quality, mainly for the detection of soluble gases, halogenated hydrocarbons, phenols, amines and metal organic compounds contained in water.

(3) Application in other industries

① Application in industrial safety production: It is used for gas safety analysis before entering hot work areas or confined spaces, mainly to determine the oxygen content and combustible gas content in the air at the site. You can use a portable gas chromatograph with a TCD detector to measure O2, H2, CO, CH4, and other hydrocarbons in the gas simultaneously. By analyzing the retention time of each component in the chromatogram, you can perform qualitative and quantitative analysis on the sample, thereby meeting the requirements for industrial safety production monitoring on site.

② Monitoring application in semiconductor process Large-scale integrated circuits have very strict quality requirements for silicon single crystals.In the process flow, to control carbon pollution, online gas chromatography can measure the trace carbon-containing components, such as CO, CH4, and CO, in the electrolytic purified hydrogen used for the reduction of polycrystalline silicon preparation. For the high-purity argon required for single crystal silicon preparation, the concentrated chromatography method can measure <0.01 umol/mol CO, <0.03 μmol/mol CH4, and <0.08 pmol/mol CO2. You can use gas chromatography technology to determine the trace organic carbon in SiHCl during the single crystal silicon production process. Additionally, you can use a gas chromatography FPD detector to detect PH3, PCl3, and POCl3 in the semiconductor silicon process.

③ In the monitoring of occupational health, online gas chromatography is an important analytical technology for the continuous monitoring of toxic substances in the air, especially various organic compound pollution. The use of online gas chromatography GC and GC-MS coupling technology can be used to perform continuous qualitative analysis and quantitative detection on site. GC-MS not only has the high column efficiency, high separation, and quantitative functions of gas chromatography but also has the qualitative function of mass spectrometry for unknown samples. With the increase in the types of occupational disease hazards and the occurrence of sudden occupational disease hazards, GC and GC-MS coupling technology will play a vital role in occupational health monitoring.